On January 29, 2026, a meeting was held in the classroom No. 1 of the educational building No. 5, where 1st-year students of the Faculty of History, Read more

Quotation gallery

Formal education will make you a living. Self-education will make you a fortune.

Faculty News

On January 30, 2026, students of the Faculty of History, Economics, and Law of Manash Kozybayev North Kazakhstan University took part in career guidan Read more

On January 29, 2026, a large-scale environmental fair "Darmarka" was held at the Manash Kozybayev North Kazakhstan University as part of the #StopMuso Read more

23 января 2026 года на факультете истории, экономики и права состоялась рабочая встреча представителей Управления государственных доходов г.Петропавло Read more

In mid-December 2025, the РА "Red Crescent Society of the Republic of Kazakhstan" held a short film competition on the theme "Fundamental Principles o Read more

On December 26, 2025, the Faculty of History, Economics and Law held a final meeting of the Faculty Council dedicated to summarizing the results of th Read more

17.12.2025 на медицинском факультете НАО СКУ им.М.Козыбаева началась экзаменационная сессия. С целью укрепление принципов академической честности, про Read more

12 декабря 2025 года, в рамках реализации плана научных мероприятий медицинского факультета на 2025–2026 годы, был проведён практический семинар с гру Read more

On December 2, 2025, the Department of Justice of the North Kazakhstan region held a lecture for students as part of the implementation of the ideolog Read more

On November 27, 2025, the Faculty of History, Economics and Law hosted a seminar by business consultant and MBA teacher Sh.I. Orazbayeva on the topic Read more

Разработка технологии переработки ротационных композитов, на основе вторичного полиэтилена, для изготовления широкого спектра технических изделий

The IRN AP26104785 project is being implemented within the framework of grant financing for 2025-2027 by the Ministry of Science and Higher Education of the Republic of Kazakhstan.

Project manager: Tyukanko V.Yu., Candidate of Technical Sciences, PhD in Chemistry (Hirsch index – 7 https://orcid.org/0000-0002-1736-0323 Scopus Author ID: 57198436102)

Project executors: Demyanenko A.V., Krasilnikov R.E., Tarunin R.A., Brilkov S.A., Litvinov S.V.

Implementation period: 01.01.2025 – 31.12.2027

Total amount of financing: 120 000 000 tenge.

Project objective: Develop a technology for the production of a wide range of technical products using recycled polyethylene through the processing of rotational composites, ensuring the efficient use and recycling of plastic waste.

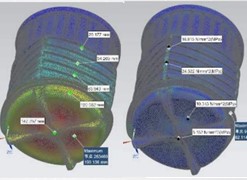

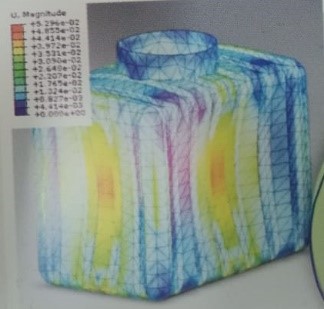

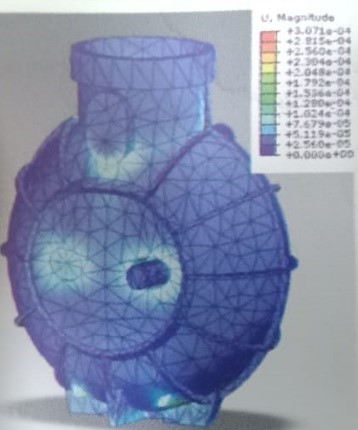

Expected results: Optimal formulations will be developed based on various compositions of secondary rotary polyethylene with improved performance and high mechanical properties of products. New designs of technical products, such as underground tanks and septic tanks, have been developed with a guaranteed high service life (taking into account the reduced mechanical properties of compositions based on recycled polyethylene). The possibility of developing a method for rapid diagnostics of internal stresses in rotoformed products by means of ultrasonic flaw detection has been studied. An industrial approbation of the proposed technology for processing rotary composites based on recycled material has been performed. The necessary regulatory and technical documentation has been developed, including the technological process and standards of the organization for at least one type of technical products.

Project Description: Today, the problem of environmental pollution from plastic waste, particularly polyethylene, remains acute. The most effective solution is its recycling. One method for recycling polyethylene is rotational molding (RM), which can be used to produce various technical products, such as underground storage tanks. However, there is currently no comprehensive technology for recycling secondary rotational polyethylene (RPE), which creates a number of challenges that need to be addressed. Firstly, it is necessary to develop optimal formulations for composites containing recycled polyethylene, which will ensure high performance characteristics of the products. Secondly, given the reduction in mechanical properties (due to high temperatures and oxidation processes) during the processing of composites based on recycled polyethylene, the material's strength characteristics deteriorate, making standard product designs incapable of guaranteeing their service life.

Therefore, it is necessary to design new structures using modern calculation methods, such as the finite element method, which will take into account the loads that occur in products, such as underground tanks, for example, at ground pressure. Due to the wide range of parameters of recycled plastic, industrial practices often encounter the problem of highly stressed products being processed with recycled polyethylene, which can lead to their failure during use. Therefore, thirdly, an equally important task is to develop a rapid method for detecting internal stress in products using ultrasonic flaw detection. Solving this problem will allow for timely adjustments to composite formulations, minimizing internal stress and extending the service life of the products. Thus, the development and implementation of new technologies for recycling secondary polyethylene, quality control using ultrasonic flaw detection, and the optimization of product designs (based on the finite element method) are promising areas that will significantly improve the environmental situation and increase the efficiency of plastic waste utilization.